To manufacture LCD panels using these massive G10 glass substrates, our LCD panel plant is 360 meters wide across the front and 400 meters deep. The plant can yield 78,000 glass substrates per month, and it has a production capacity equivalent to approximately 470,000 70-inch LCDs per month.

Ultra Large-Screen LCDs Made at

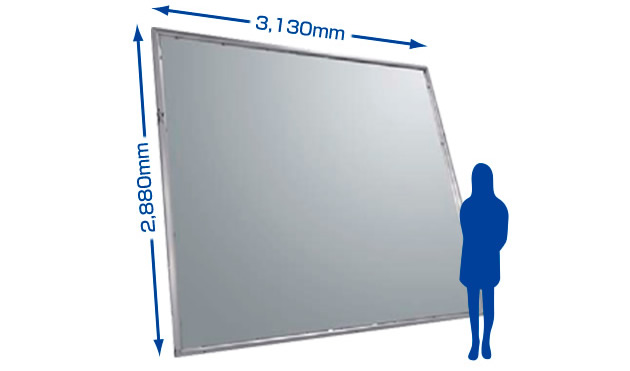

World’s First and Only* G10 Plant Using Large (3,130mm * 2,880mm)Glass Substrates

10th Generation (G10) Glass Substrate

One of these glass substrates would cover the floor of a nine-square-meter room. Eight 60-inch displays or six 70-inch displays can be produced from a single substrate. By effectively manufacturing large-screen LCDs, we can maximize our advantage in making 60-inch-and-larger LCDs.

SDP is the first company to make LCDs from G10 glass substrates--a new chapter in the story of large-screen LCDs.

State-of-the-Art Plant Maximizes Advantages of G10 Glass Substrates to Realize Highly Efficient Manufacture of Large-Screen LCDs

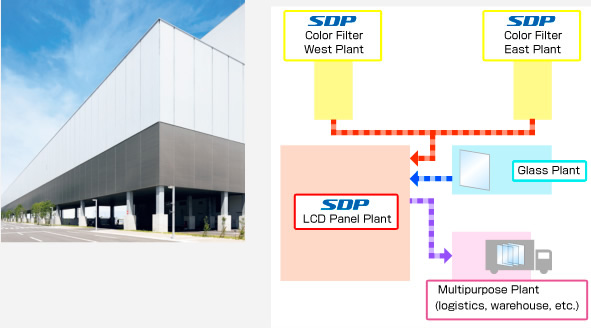

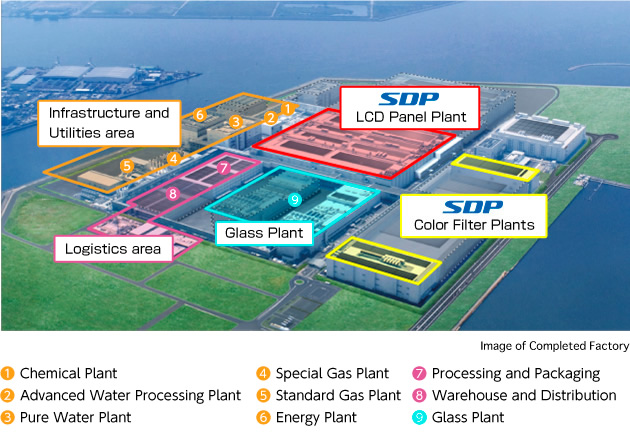

SDP’s Own Plants Manufacture LCD Panels and Color Filters

■LCD Panel Plant

■Color Filter Plants (East Plant, West Plant)

Color filters, a key component of LCD panels, are manufactured in-house in two plants. These plants do more than just provide high-quality, cost-efficient products; they also continue to develop products with new functions and greater performance.

SDP Works Jointly with a Cluster of Related Companies Possessing State-of-the-Art Technologies

SDP is located in the same industrial park as extremely advanced companies that deal in materials (glass, liquid chemicals), energy (electricity, gas, water), and other fields. We all work together like one big factory. This synergy helps us realize maximum efficiency in manufacturing.

Inter-Building Transport System Contributes to Efficient ManufacturingInter-Plant Transport System Links Buildings and Contributes to Efficient Manufacturing

The related plants are linked like arteries, so that materials can be transported between plants using minimal time and energy. The transport paths total approximately 1.9 kilometers (1.2 miles) in length and are much more efficient than trucks at delivering the large, thin G10 glass substrates. Using this transport system contributes to the efficient manufacture of large-screen LCDs.